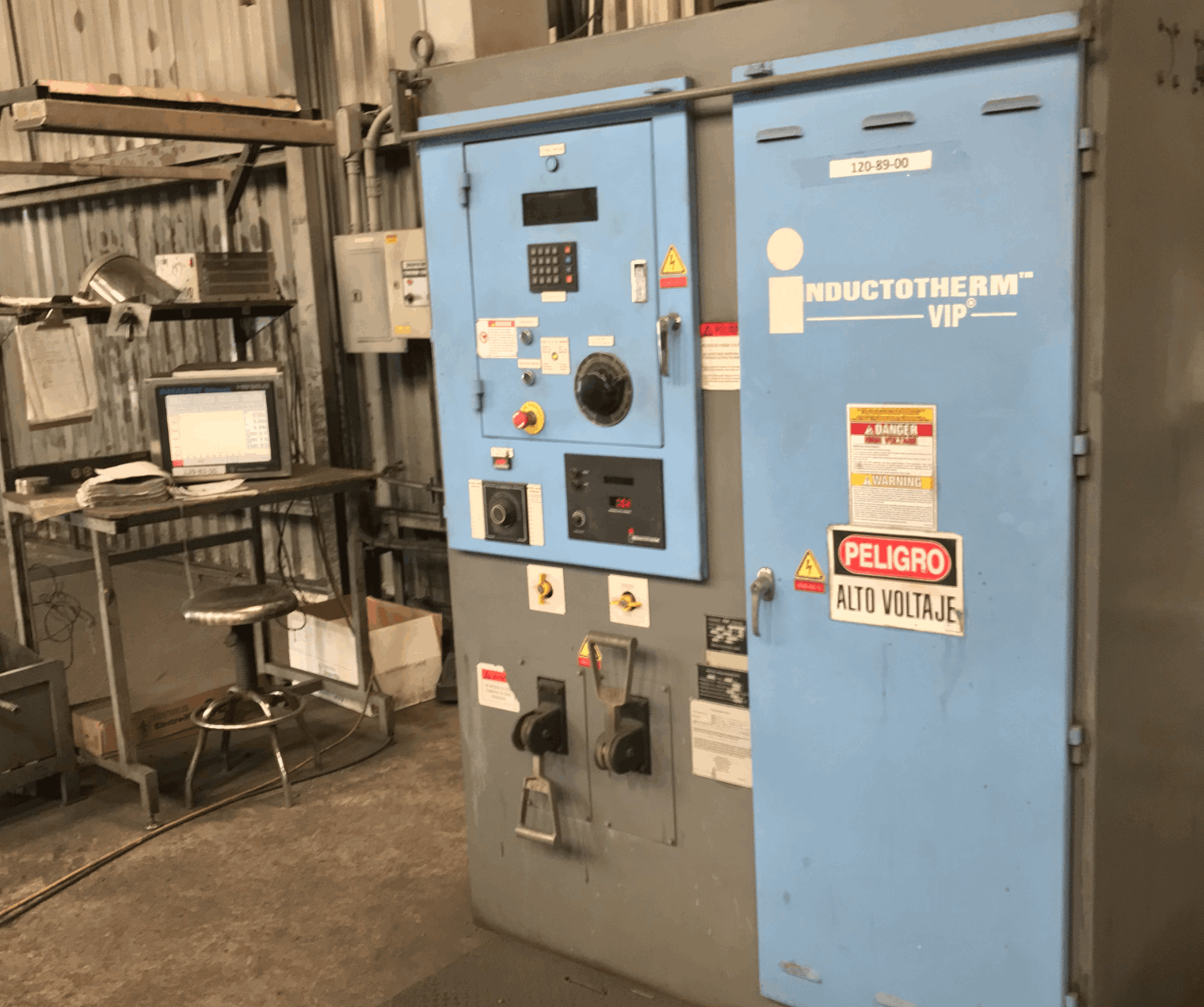

The main components of an induction heating system are:

The coil body, made up of the force coils (where they are physically arranged is where there is more agitation in the clean bath) and the cooling coils, the power supply, the charge coupling stage, a cooling station , the refractory material that protects the coils from the liquid bath and the piece to be treated.